LED2WORK and IO-Link

IO-Link: Communication standard of the present and future

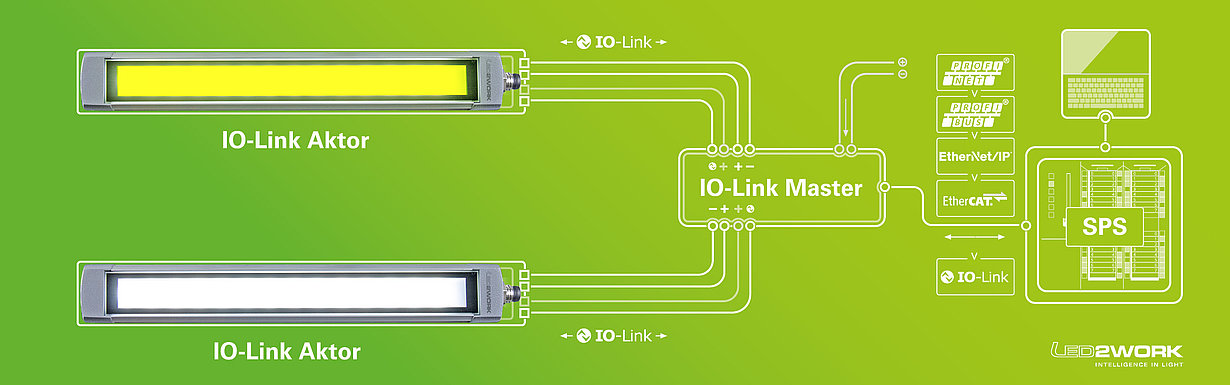

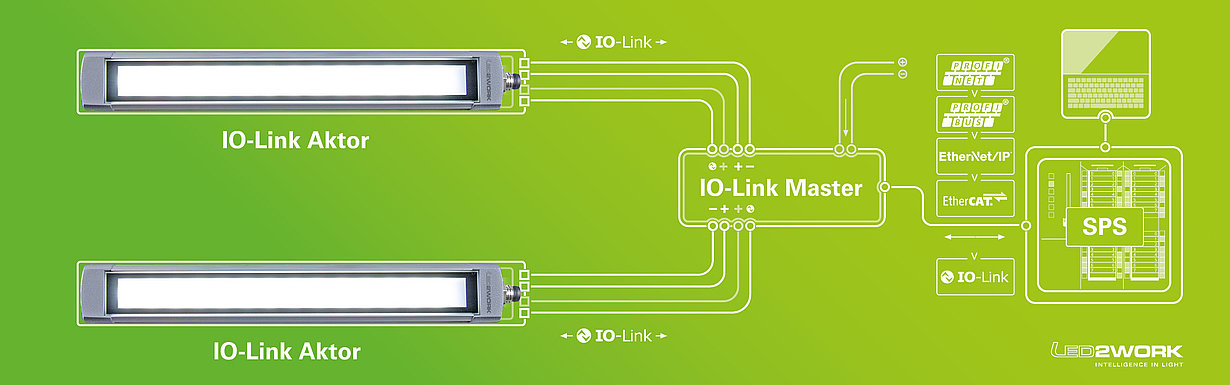

IO-Link is a manufacturer-independent communication technology for connecting sensors and actuators to higher-level controllers in automation.

IO-Link enables bidirectional communication between devices at the lower field level, i.e. sensors and actuators in automation, and higher-level control systems such as a programmable logic controller (PLC).

IO-Link was developed to compensate for the weak points of fieldbus installations or parallel installations for controlling sensors and actuators in automated systems.

What is the decisive advantage of IO-Link?

In short: IO-Link makes automation easier!

Why?

Compared to previous automation solutions, the installation and integration of sensors and actuators has become much easier with IO-Link.

Furthermore, the use of sensors and actuators with IO-Link offers improved diagnostic options, simpler parameterization, high flexibility and - what is very good - the simple integration of devices from different manufacturers into one system.

LED2WORK sets the standard for LED lights for automation with IO-Link

Advantages of IO-Link-capable LED luminaires from LED2WORK

Intelligent control and configuration

The integrated IO-Link circuit board enables intelligent control of the LED2WORK LED light. It is possible to adjust the brightness, light change from white light to signal colors, RGB color change, flashing frequency and set other parameters.

Easy integration into automated systems or other installations

The configuration and control of light and signals is carried out via the higher-level control system, which increases the flexibility and adaptability of the system. The system does not have to be an automated system. Control systems for machine tools or similar are also suitable, as long as the IO-Link master is compatible, i.e. speaks the same language.

Diagnostic capability

With the extensive diagnostic options, any problems or failures can be diagnosed in real time, which makes maintenance and troubleshooting much easier compared to conventional systems

Parameter changes during operation

The IO-Link capability makes it possible to change the parameters of the LED2WORK LED luminaires during operation and thus quickly adapt them to changing requirements. It is also easy to replace LED luminaires during an ongoing process.

Reduced installation effort

LED2WORK IO-Link-capable LED luminaires can be used with standard connections and cable systems, which reduces the amount of cabling required. The minimum requirement is a simple, three-core sensor cable. Bidirectional communication takes place via the same cable that provides the power supply.

High flexibility and scalability

LED2WORK IO-Link capable LED luminaires offer high flexibility and scalability of the system. The number of connected luminaires can be easily reduced or expanded without the need for major changes to the cabling or configuration.

Energy efficient

LED2WORK LED luminaires are already very energy-efficient by design. Precise control of the IO-Link-capable LED luminaires can further increase efficiency, as brightness and operating status can be adjusted as required.

The integration of LED2WORK IO-Link-capable LED luminaires is an intelligent, flexible and efficient solution for lighting and signaling in automated environments.

What is required for the clean installation of IO-Link-capable LED luminaires?

In order to carry out an installation and operate our LED lights with IO-Link, at least the following components are required:

LED light with IO-Link:

This refers to LED luminaires such as TUBELED_25 RGB-W IO-Link and upcoming LED luminaires from LED2WORK that support the IO-Link communication standard.

If the LED luminaire is integrated into an IO-Link installation, it becomes an actuator. The LED luminaire can then transmit various parameters via the IO-Link protocol and in turn execute commands from the control system.

IO-Link-Master:

The IO-Link master is the interface between the IO-Link-capable LED light and the higher-level control system.

The IO-Link master is a kind of interpreter that translates and enables communication between the connected LED luminaire on the one hand and the control system on the other.

IO-Link masters have one or more ports for IO-Link devices. If the number of ports is not sufficient, an IO-Link hub can be plugged in to provide additional ports.

Connection cable:

Connection cables are required to connect the IO-Link-capable LED light to the IO-Link master. The cables and attached connectors must meet the requirements for the transmission of digital signals and power.

The lower limit for connecting the IO-Link-capable LED light to the IO-Link master is a three-pole sensor cable, which should not be longer than 20 m per connected device as a guideline.

The connection from the IO-Link master to the controller, on the other hand, must be adapted to the specific conditions in order to enable clean communication via fieldbus, TCP/IP or another communication protocol specified by the controller.

Power supply:

Both the IO-Link-capable LED light and the IO-Link master require power.

As a rule, the IO-Link master is connected to the 24 V DC supply voltage commonly used in industrial automation. The LED light is then supplied with voltage by the IO-Link master.

control system:

A higher-level controller, such as a programmable logic controller (PLC) or a decentralized control system (DCS), is required to process the information from the IO-Link devices and perform control tasks. The parameterization of the connected IO-Link devices is also possible here.

Configuration tool:

An IO-Link configuration tool is required to configure the IO-Link master at control level and to parameterize the connected LED light.

This tool can be hardware or software-based and is usually included in the scope of delivery of the IO-Link master.

Newer controllers that are already designated as IO-Link-capable can provide integrated configuration tools for IO-Link applications.

Infrastructure:

For safe installation, both the LED light and the IO-Link master require a suitable infrastructure such as cable trays and mounting devices.

„Anyone who has understood and does not act has not understood.“ Wang Yangming