Markus Wiedmann

Chief Sales Officer

IO-Link: Advantages for Lighting Solutions in Machinery and Plants

Automation and connected manufacturing are currently the major trends in industry. However, many of the technical components used in these areas were never designed for a networked environment. As a result, solutions are often more cumbersome and expensive than they need to be.

The IO-Link standard aims to change this and simplify many aspects. How does IO-Link work, and what advantages does it offer? You'll find out in this article. We'll also show how you can implement lighting solutions in machinery and plants using IO-Link in particular.

Simply Explained: What Is IO-Link?

IO-Link is a digital interface for communication in automation technology. It enables sensors, actuators, and controllers from various manufacturers to be connected into one overall system and operated via software.

For example, you can use software to switch intelligent IO-Link luminaires on and off in a network, control brightness, color, and flashing behavior, and read operating data such as temperature and service life.

This allows for the implementation of various automation scenarios, such as: “Blink red if the machine reports an error” or “Reduce brightness if your temperature exceeds 70 degrees Celsius.” For this reason, IO-Link is frequently used by manufacturers of machines, systems, and automation solutions.

Compared to previous, mostly manufacturer-specific systems, IO-Link offers many benefits: it is relatively easy to install, more cost-effective and space-saving, and provides significantly more options for application.

IO-Link Is on the Rise

In 2023, 15.9 million IO-Link devices were newly installed, representing record growth of 89% compared to the previous year. The total number of installed IO-Link nodes is now an impressive 51.6 million. The growing numbers on the market underscore the success of IO-Link.

Visit the IO-Link Consortium Website

Functionality and Technical Components

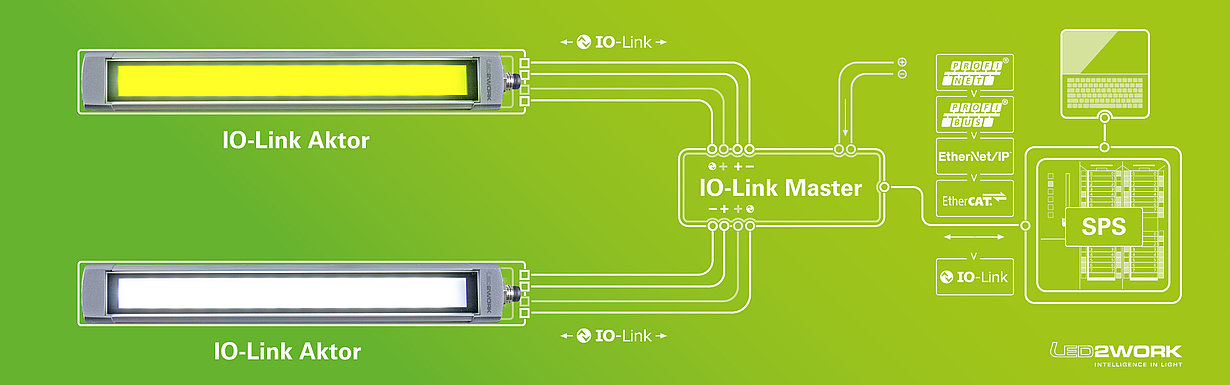

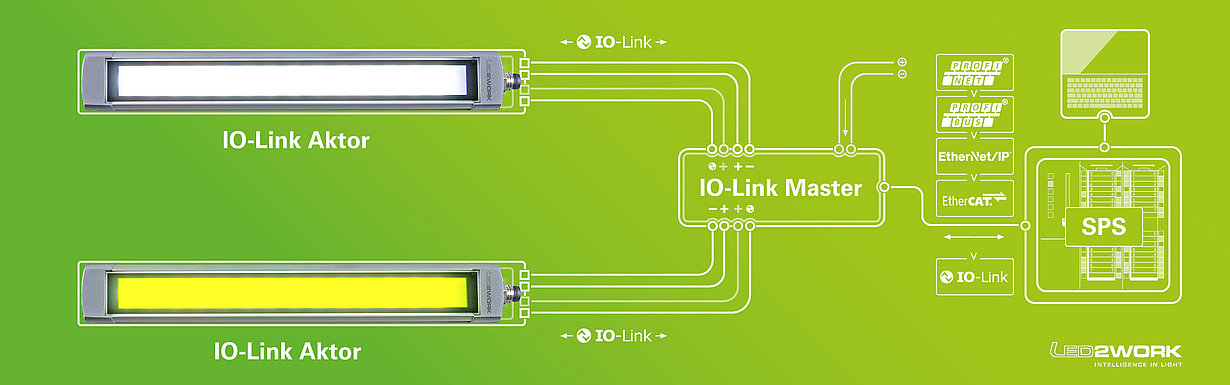

Technically speaking, IO-Link is a standard for digital, bidirectional point-to-point connections for communication between an IO-Link master and an IO-Link device (International Standard IEC 61131-9).

IO-Link Master

The IO-Link master is the central control unit of the system. It establishes the connection between the IO-Link devices and the higher-level control layer, such as a programmable logic controller (PLC) or a fieldbus.

A master can have multiple IO-Link ports, each of which connects to one device. Communication is always a point-to-point connection between the master and the respective device.

IO-Link Devices

IO-Link devices are the field devices connected via IO-Link. These can be sensors (such as motion detectors and RFID readers) and actuators (such as luminaires, valve manifolds, and motor starters).

The devices communicate with the master via IO-Link, sending process data and receiving parameter and control data. They are also powered through the IO-Link connection.

Connection and Connection Technology

IO-Link transmits data and power via an unshielded, standardized 3-wire plug cable. M8 or M12 connectors are typically used for connecting the master to the device. The maximum cable length is 20 m.

Network Integration

IO-Link serves as the interface between the field devices and the lowest level of automation. The actual networking of the automation components takes place using systems like fieldbuses (e.g., PROFIBUS, PROFINET) or Ethernet-based protocols. IO-Link complements these technologies and bridges the gap to the sensor/actuator level—the so-called “last meter.”

Typical Application Scenarios in Lighting

Some specific application scenarios for IO-Link in lighting include:

- Adaptive lighting in production: adjusting lighting to the manufacturing process and the operating personnel

- Status indication on machines: luminaires indicate operational status, such as production, malfunction, maintenance, etc.

- Lighting control in storage racks: intelligent luminaires save energy and indicate free storage locations.

- Emergency lighting with evacuation scenarios: in an emergency, luminaires guide employees safely to the exit.

Advantages and Benefits of IO-Link

IO-Link offers a variety of advantages for automation solutions. In summary, they can be planned, installed, and operated more efficiently.

Simplified, Cost-Effective Cabling

Instead of laying separate cables for power and signals for each luminaire, in the simplest case a single unshielded 3-wire standard cable is sufficient. This transmits both the control and parameter data (from the master to the luminaire), the operating data (from the luminaire back to the master), as well as the supply voltage for the luminaire.

Thanks to the point-to-point connection between the IO-Link master and device, the complex addressing and termination required by classic fieldbuses is no longer necessary. This significantly reduces wiring and installation effort, saves space in the control cabinet, and lowers the risk of wiring errors.

Manufacturer Independence and Easier Procurement

IO-Link masters and devices from different manufacturers are compatible with each other and can be combined in any way. Users are no longer dependent on proprietary solutions from individual providers but can select the components best suited to their application.

IO-Link reduces the variety of variants and the storage effort for spare parts. Instead of keeping a separate version for each type of luminaire in stock, a few IO-Link luminaires, which can be flexibly parameterized, are sufficient.

Extended Diagnostics and Remote Maintenance

IO-Link devices, such as our luminaires, transmit not only process data but also extensive status information and diagnostic messages. For example, operating hours, temperature, or the condition of the luminaire can be monitored remotely.

This data enables predictive maintenance and servicing. Impending failures can be detected early and corrected before lighting outages occur. In the event of a service need, IO-Link supports quick troubleshooting and resolution thanks to detailed diagnostic information.

"The clear advantage of IO-Link is the simple commissioning, easy parameterization, and the integrated feedback system. This simply saves me money."

Parameterization and Configuration via IO-Link

Another advantage of IO-Link is the ability to parameterize and configure devices via the controller. Instead of having to set each luminaire individually on site, parameters such as brightness, color temperature, or lighting effects can be adjusted centrally through the software control, even during operation.

This speeds up commissioning and makes it possible to quickly adapt the lighting to changing production conditions. Replacing luminaires is also simplified: the new luminaire automatically adopts the preset parameters.

Reduced Space Requirement in the Control Cabinet

Eliminating terminals, relays, and fuses for lighting control significantly reduces space requirements in the control cabinet. Depending on the design, a single IO-Link master can connect multiple luminaires via a compact module.

Additionally, many IO-Link masters are available in IP65/67 protection class and can be installed directly in the field. A control cabinet is then no longer required.

Functions of Intelligent IO-Link Luminaires

The TUBELED_25 RGB-W IO-Link from LED2WORK already comes with many features that can be utilized via IO-Link. It combines high-performance workplace lighting and signal lamp functionality in a single device.

Acquisition of Operating Data and Condition Monitoring

The luminaire measures comprehensive operating data and makes it available via the IO-Link connection: among others, operating hours, temperature, and over-temperature log. It continuously monitors its own status and reports when critical values, such as the expected service life, are reached.

Individual Adjustment of Brightness and Color

All 4 channels (RGB + white) can be controlled independently and dimmed seamlessly.

Integrated Effects

Effects such as flashing, strobing, color changes, and glowing can be enabled through the controller.

Learn More About LED2WORK and IO-Link

Conclusion

One can confidently say that IO-Link is revolutionizing connectivity in industry, including lighting. The standard greatly simplifies the installation, maintenance, and control of luminaires. IO-Link also contributes to greater efficiency, for instance through predictive maintenance and optimized process control.

Successes and Future Focus

Another highlight of the assembly was celebrating the impressive market figures. In 2023, 15.9 million IO-Link devices were newly installed, representing record growth of 89% compared to the previous year. The total number of installed IO-Link nodes is now an impressive 51.6 million. The growing volumes in the market underscore the success of IO-Link. At the same time, there was intensive discussion on how to continue advancing IO-Link to meet the constantly changing demands of the industry.